In powder coating, the importance of a properly selected and properly maintained racking system cannot be over emphasized. These areas play an important role in the selection of a properly designed racking system:

- The pretreatment system for drainage.

- The conveyor system for proper grounding

- The booth design for ease of application.

- Loading and off-loading areas for proper space.

The efficiency of your electrostatic application equipment depends on proper grounding from the conveyor system to the parts in process. Powder applied over and over on the racking system will create a highly insulated surface that will reduce the efficiency of the coating application equipment. Therefore, the racking system will require cleaning on a regular basis.

The efficiency of your electrostatic application equipment depends on proper grounding from the conveyor system to the parts in process. Powder applied over and over on the racking system will create a highly insulated surface that will reduce the efficiency of the coating application equipment. Therefore, the racking system will require cleaning on a regular basis.

This can be accomplished in a number of ways, the most common of which is the removal by incineration (burn off). The racks are placed on a furnace and elevated to a temperature high enough to burn the coating to an ash that is easily removed with water.

Another method commonly used is chemical removal, although this process is often messy, expensive, dangerous and sometimes illegal.

From the most elaborately designed racking system to the simplest style “S” hook, regular cleaning of the racking system will insure good grounding and maximum transfer efficiencies of powder resulting in lower material costs.

See this detailed article about racking system considerations from Jerry W. Trostle of Nordson Corporation:

For both existing systems as well as entire new systems, rack design should be considered equally with all other areas of the system. Without the proper rack design even the most automated and sophisticated systems will not operate correctly.

Proper parts racking will have a major impact on the following items:

- The operating efficiency of the Powder System

- The correct application of the Powder coating

- Health and safety of the operators

- Costs associated with rack fabrication and their maintenance

MAXIMIZE SYSTEM EFFICIENCY

When more productivity is required from a powder system, the first area of focus is normally on increasing the line speed of the system. This might not be the answer; making the most of the line space that you have at your current line speed is the first goal to achieve.

For example, if your line has been designed to operate at 10 ft per minute, then 10 ft of conveyor space will be available every minute. Maximizing this conveyor space is essential.

Depending on the size, weight and configuration of your parts you may be able to multiple hang your parts in a way that will make better use of your available line space.

The better your line density the lower your cost per piece.

This is because many of the costs of operating your washer, dry-off, and cure oven will remain the same whether one part or one thousand parts will pass through your system in an hour. The cost will be spread out over more parts with better line density.

With proper rack design the line speed may even be decreased.

If you are in the process of designing a powder system from the ground up, the best place to start is with the racking. This will determine the line speed that will be the key to the system’s size and cost.

Proper rack design can lower your initial capital outlay.

GREAT TIP: Determine the number of parts you wish to coat, the number of shifts that you will run and the largest part size then base your racking arrangements around this. Fill the line area with the smaller parts to maximize your efficiency by designing your racks to hold as many parts as practical in the remaining area. Once you have determined your line density capability, you can then calculate the line speed necessary to meet your requirements.

Generally the lower the line speed, the lower the cost for your complete powder system.

When designing the racks for your parts, you need to consider all aspects of the system that you will be using.

For example, will the parts be washed in a spray or immersion washer where water may be carried out causing cross contamination in the wash stages or improper drying of the part in the dry-off oven. Racking must allow for proper drainage of the parts. In most Infrared curing systems it is important for the IR emitters to see the part that is to be cured. Racking must be designed to maximize this.

PROPER APPLICATION OF POWDER COATING

Rack Design will have a major impact on the application of the powder to your parts.

Difficult areas to coat need to be hung so both the automatic guns and/or the manual operators can easily apply powder to these areas. It is important that the rack not become a “robber” of powder from your part.

If the rack is too massive, more of the powder may be applied to the rack than to the part itself.

This will reduce your system’s efficiency by decreasing or even eliminating the ground.

It is critical that the rack contact the part in a way that will leave the smallest contact point. This will minimize areas that may need to be touched up after the part is removed from the line.

***If the part has not been racked in a way that insures proper grounding during the coating process, it will be difficult, if not impossible, to insure proper coating of the part. See this article on Proper Grounding

Without a ground to the part, film thickness will be difficult to control and driving powder into certain areas will be nearly impossible. This is so because the part will “charge up” like a capacitor and repel the charged powder as it continues to be applied.

GREAT TIP: Don’t use chain to hold your parts: rod, bar stock or aircraft cable make better means of hanging parts compared to chain.

Because the powder builds up in the links, more frequent cleaning of the hooks will be required.

GREAT TIP: use square stock rotated 45 degrees for racking your parts.

This will provide a small sharp contact point which will insure a consistent ground to the part.

It will mask the point of contact on the rack minimizing the frequency of rack cleaning while at the same time causing the smallest racking mark on the part.

This material is also very strong for its size and can hold more weight.

If parts are hung too close together because of racking arrangement, it will be difficult to achieve proper film thickness in the areas between the parts.

From experience it has been found that a minimum of about 3- 6″ distance should be kept between racked parts. This will vary depending on the depth and the mass of the part. ~

From experience it has been found that a minimum of about 3- 6″ distance should be kept between racked parts. This will vary depending on the depth and the mass of the part. ~

Hanging parts too far apart causes problems, too.

If the parts are hung too far apart, it can make film thickness control more difficult as well. Because of the nature of electrostatics, if the parts are hung at great distances, you will experience heavy buildup of powder on the edges of the parts.

Within the limits mentioned it is normally to your advantage to achieve high density of parts on the line in terms of best coating uniformity.

HEALTH AND SAFETY OF OPERATORS

Operators’ health and safety is the most important aspect of rack design.

As with many of the other concerns associated with the design of your parts racks, simple things can effect the performance of the system.

The main cause of fires in a powder system is improperly grounded parts mainly caused by dirty part racks. As powder builds up on the racks, parts may not be grounded.

With ungrounded parts, a charge can buildup in the part that will discharge to ground and ignite the powder as it is being sprayed.

It is essential to design the racks to always contact the part to insure grounding.

It is also necessary to clean the racks as often as necessary, but how often is this?

This varies depending on the size and weight of the parts (heavy parts on the racks often extend the time), the design of the rack and many other issues.

Some people clean the racks every time and others may do it once a week. The key issue is that ground is maintained.

GREAT TIP: The use of a megaohm meter is a good idea to confirm that a ground is present.

Many times racks will be sent around the system without parts hung on them. Powder will coat the contact points eliminating the ground the next time parts are hung. Make sure that if parts are not to be hung on the racks that the rack be removed until needed.

If universal type racks are to be used, covers can be fabricated to mask contact points on the rack if parts are not hung in these areas. Many of the new automated powder systems have the ability to spray powder only when parts are present.

***Other aspects of the health issue include the proper height for lifting and loading the parts onto the racks ( conveyor height from the floor), ease of loading the parts onto and unloading of the parts as the conveyor is moving, and ease of hanging the actual rack onto the conveyor.

These areas are often overlooked in the design phase of the system.

COSTS ASSOCIATED WITH RACK DESIGN AND MAINTENANCE

The costs of designing and fabricating the racks for your system can be high.

Many times this is overlooked when budgeting for the powder system.

This underscores the importance of designing the racks early in the process.

The following items are concerns in designing racks for your system:

- Masking requirements

- Rack cleaning

- Variety of parts to be run

- Powder coating application

GREAT TIP: When designing your racks it is a good idea to layout on the floor as many of the different parts as possible to see how they will fit into your available line space. This will also help you to find the best points at which to hook them to the rack.

The ideal situation is to have one rack for all of your parts.

This is normally not possible so minimizing the number of different racks is your best alternative.

Many systems will have one rack type for the large parts and two or three for the smaller parts.

It is possible to have one basic carrier that will use several attachments for the various parts that can be hung on or removed easily as needed.

This process racking analysis can be time consuming initially but will save much time and money later.

The parts that need to be powder coated may required some masking.

This can be a time consuming and costly exercise.

There are excellent manufacturers of masking tapes, plugs and caps that can be used at the high temperatures that are required in the powder coating application.

GREAT TIP: You might consider designing your part rack to act as a mask.

One example would be to use a part rack fixture that holds four parts on a rack in a way that would mask the interior areas that must be bare metal.

This fixture reduces masking time and because of the way that the parts are hung the rack requires fewer cleanings to maintain proper grounding.

Rack cleaning is a major area of concern.

As mentioned earlier maintaining a proper ground is imperative so you must keep your rack clean to insure this. Stripping of powder coat from the racks may use one of several ways:

- Burn off ovens

- Chemical stripping

- High temperature chemicals

- Low temperature salts

- Abrasive Blasting

- Hot sand fluidized beds

- High pressure water or freezing

Each of the different means of stripping the racks has their distinct advantages and disadvantages; a thorough investigation of your options will determine what is best for your needs. It is important to keep in mind that the manner in which you plan to clean your racks will influence your design. You will need to fabricate the racks of a material and gauge that will withstand the cleaning process.

For example, if you plan to burn off your racks, a very light weight rack might not withstand the heat involved with the process.

The design of the rack will determine how much stripping will be required.

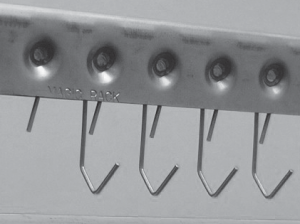

In addition, you might consider replaceable hooks. When the actual contact point becomes coated to the point of no ground, the hook is removed, discarded and replaced with a new uncoated one. These work extremely well on small or light weight parts.

SUMMARY

With proper forethought racking can be a means of greatly improving the efficiency and safety of your powder system. If you or your in-house staff do not have the time or the resources to devote to this part of your system there are many good consultants and people who specialize in rack design and fabrication.

Your investment in this area will insure profitability of your powder system for years to come.

Related Resources

- Building Environment Enclosures

- Engineered Buildings

- Powder Coaters Corner

- Powder Coating Industry Research

- Contact

Racking System Design and Maintenance – Powder Coating