From the experts at Crosslink Paints:

Touch up paint has been saving powder coaters and manufacturers time, resources, & money. Whether it is fixing common powder coating problems like hook marks and hard to reach areas or scratch marks caused by transportation and handling, touch up paint is the quickest solution to the problem.

Even though touch up paint can save you from having to re-coat your products, there are some facts and limitations you should know that will help you choose the correct product for your application.

What Is Touch Up Paint Typically Made Up Of?

The most common paint touch up paint manufacturers use today is an Acrylic Enamel paint. This paint is most commonly used because it does a great job of preventing rust, plus it is a fast air-drying paint that typically takes 15-30 minutes to dry, 1-2 hours to handle and 7 days to fully cure.

The gloss and color retention when exposed to the sun typically holds up at the same rate powder coating does given that the resin is not a super durable. This is approximately 5% a year until the gloss level reaches 20%.

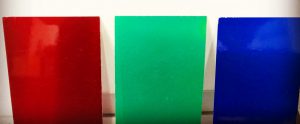

What Are The Two Types Of Color Matches?

Color Standard Match

Color Standard Match

One of the most common color standards used by powder coaters is the RAL Standard. Powder coating manufacturers & touch up paint companies will try their absolute best to manufacture an exact match to this color standard using different materials.

Even though both materials are intended to match each other, this does not account for the different type of circumstances they might encounter when being applied together.

Transparent Colors

Custom Paint Match

A custom paint match is when a color is manufactured based upon a sample provided to the touch up paint manufacturer. A touch up paint company will try their absolute best to match both gloss and color of the sample provided even though the sample might have a great variance in surface color, surface texture, film thickness, gloss level, and material composition.

What Are The Factors That Make an Exact Match Difficult?

There are a lot of factors to consider when manufacturing a color, but with the technology we have today we can match colors to the point the human eye can’t detect a difference.

Below are 7 variables that affect the way a color match will turn out:

1. Materials used to create a matched color

The one factor that most affects the color-matching process is the materials used to make the color. For example: powder coating consists of a solid powder being liquefied onto a metal substrate then being converted back into a solid essentially forming a hard plastic film. But because the materials used to match a color are completely different from the conventional touch up paint, there will always be a slight variance in the look of the two finishes.

2. Gloss level = level of reflection measured as a percentage

Color Gloss is the level of reflection a color gives off at a 60 degree angle. The level of gloss is measured in percentages with a gloss meter with 100% being the shiniest and 0% being the dullest.

Here are some common terms used when deciding gloss level:

High Gloss 85+%

Full Gloss or Glossy 75-85%

Semi Gloss 50-75%

Satin 30-50%

Matte or Eggshell 20-30%

Flat 0-20%

Metallic Effects

3. Metallic – the hardest colors to match

Metallic colors are one of the hardest colors to match. This is mainly because the metallic flakes will cause the actual color to appear light or darker depending on the angle the metallic flakes lay, what angle you look at the finish, and how the light is reflecting off the finish. This is why touch up paint manufactured for a powder coated metallic finish will not match at certain angles but it is still the best option other than completely re-coating the entire piece.

4. Metamerism Effect

This can be defined when two colored samples appear to be the same shade under one light source but appear to be different shades under a second source. This is a battle all touch up paint and powder coating manufacturers face when formulating a color.

5. Surface Color – substrate color bleed-through effect

The color of the surface, or what we refer to as the substrate you are painting on, will have an impact on the color. This is commonly known as the bleed-through effect. If the surface you are painting on is darker than the paint you are applying, this will cause the paint to appear darker than it actually is. This would be opposite if you were to paint on a lighter surface.

6. Surface Texture – second hardest colors to match

Textured finishes can cause a color to appear duller and darker compared to a traditional smooth glossy finish. This is caused by light reflecting off the textured surface giving a shadow like effect. Touch up paint cannot simulate this effect in an aerosol can without having a two-part system. This makes Surface Texture the second hardest factor when color matching paint.

7. Film Thickness – aka coating Mil thickness

Film Thickness is the amount of paint that separates the surface substrate to the outside finish layer of paint. This layer is measured by a gauge using Mil thickness instrument. We always recommend you have a good Mil thickness to help separate the earths natural elements – water and oxygen – from reaching the unprotected metal substrate thus causing rust.

Film Thickness can also be tied back to surface color and gloss level. In order to completely remove bleed-through, you need a good 1-2mil film thickness to combat this effect. When using a paint that has a gloss level under <85%, multiple coats can increase the gloss level by upwards of 10%+.

Conclusion

Color Standard Matches are a great option but they don’t necessarily account for all of the factors above which could lead to the touch up paint coming out slightly different from the painted surface that is supposedly the exact same color. Ultimately the best way to get a great color match is to match a sample that the paint is going to be applied too. This removes a lot of factors that make an exact color match difficult.

The only down side is that custom paint matches typically require a minimum order sizes by most touch up paint manufacturers. This is why a color standard match can be a great alternative depending on your application.

Want to learn more about custom matched touch up paint?

Email Gabe: Sales@crosslinkpaints.com

Related links:

Touch up & Color matching Suppliers

Powder Coating Powder Suppliers

Testing Instruments (Coating Thickness Measurement devices0

Test Panels